We regularly appraise food processing plants, and one constant is that they are all fascinating. From the basics of rice and almond processing, the specialty equipment of row-crop packaging and winemaking, to the intricacies of legacy facilities, I remain amazed by the technology.

We regularly appraise food processing plants, and one constant is that they are all fascinating. From the basics of rice and almond processing, the specialty equipment of row-crop packaging and winemaking, to the intricacies of legacy facilities, I remain amazed by the technology.

When I was hired by a CPA to appraise his client’s evaporation and spray dry facilities for an inheritance situation (IRS Estate and Gift Tax Return), I took the opportunity to expand my knowledge of the freeze-dried food processing industry. Several years ago, I’d valued a meat freeze-drying facility vertically integrated with a large pet food manufacturer. I wasn’t surprised that the current assignment was substantially different.

Spray dry process

Spray drying, as you probably know, creates powder from a liquid or slurry through rapid drying with a hot gas. If you’ve ever used a powdered milk product or a whey protein powder, you’ve consumed a spray-dried product; the process is indispensable to the dairy industry. And because the process is significantly faster than other drying methods it’s used across the board for processing thermally sensitive materials – such as food and pharmaceuticals – as well as heat-resistant materials to create paint pigments, ceramic materials, catalyst supports, and micro-algae products.

History of technology

Originally patented by Samuel Percy in the United States in 1872, spray drying equipment and techniques were constrained by practical difficulties in operating them continuously. The first known spray dryers used nozzle atomizers; rotary atomizers appeared several decades later. Technology continued to evolve through the early 1900s, eventually becoming part of the commercial processed food revolution of the 1920s that featured canned and frozen foods. To this day, its primary use in the food industry has been milk powder production.

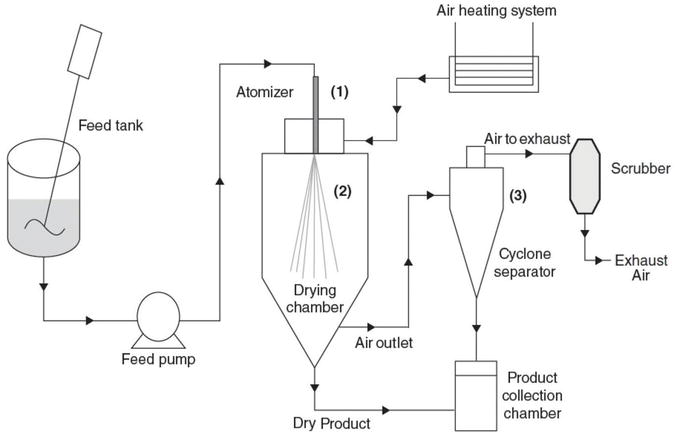

When World War II created an imperative need to reduce the weight and volume of food and other materials, interest and use of spray drying technology accelerated. Post-war, continued research and development the spray-drying continued, expanding the possibilities into pharmaceutical, chemical, ceramic, and polymer industries. Rather than tell you everything about spray-dry technology here, I refer you to a great resource at ThomasNet and to Intechopen, which provides the following graphic and explanation.

As shown, a solution is pumped to an atomizer, breaking up the liquid feed into a spray of fine droplets. Then, the droplets are ejected into a drying gas chamber where the moisture vaporization occurs, resulting in the formation of dry particles. Finally, using an appropriate device, the dried particles are separated from the drying medium, being then collected in a tank.

Atomizers: Dispensers & nozzles

Like many kinds of food processing, spray drying depends upon dispersers and nozzles, chillers, boilers, fans, compressors, pumps, trailers, tanks, and packaging equipment. Understanding the type and use of dispersers and nozzles used in a spray drier helps delineate the different uses: food processing; chemical, polymeric, pharmaceutical, biotechnology processing; and medical industries.

Of the three main conventional atomizers – rotary, hydraulic nozzle, and pneumatic nozzle – most food processing depends upon rotary, a high-efficiency technology that can handle high feed rates without clogging. The pneumatic nozzle, which provides better control over particle size, is often used for chemical or inorganic materials.

Atomizers, dispensers, and nozzles are, of course, used throughout the manufacturing industry. Their use isn’t limited to spray drying. Another use I’m especially familiar with is glass coating.

Moisture control

Evaporators, or drying chambers, are critical pieces of equipment in spray drying facilities. When the liquid gets sprayed through the atomizer or nozzle, heated gas in the chamber quickly binds with it, resulting in the evaporation of the solvent from the liquid. The different configurations of drying chambers are defined by the flow pattern between the hot gas and the spray of droplets: co-current flow, counter-current flow, and mixed flow.

In a co-current flow, the atomized spray and the heated gas enter at the top of the drying chamber, flowing through it in the same direction, creating an atmosphere of moderate temperatures. This is useful for food processing since it avoids degradation caused by overheating.

For processing heat-resistant materials, the counter-current design pattern is considered the most efficient. Spray and hot gas are introduced at opposite ends of the chamber, with the atomizer above and the air supplied from below.

Mixed flow, a combination of co-current and counter-current, is also limited to heat-resistant materials. The atomizer feed in from the bottom of the chamber, rising into the current of drying gas entering from the top of the chamber, which eventually pushes the drying materials to the bottom of the chamber.

Achieving optimal droplet-to-particle conversion of product depends not only upon which flow is being used but also upon regulating the minimum temperature required for evaporation of the solvent and the minimum drying time needed in the chamber to ensure adequate drying of the resulting particles.

Appraisal analysis overview

In most cases, because no other practical alternative uses exist for most specialized equipment such as that used in the food processing industry, current use and potential use are the same. Material handling and support equipment, on the other hand, often has wide use in many industries. This creates a situation where an appraisal most appropriately uses different value approaches to value different categories of equipment. Specialized equipment is usually valued through cost approach methodology, which is primarily recommended for equipment with no active market and significant installation costs. General equipment is appraised through sales comparison approach methodology because a well-documented active market for those assets provides a reliable source of information.

Obsolescence factors

Obsolescence factors are an important consideration in any equipment appraisal. We’re especially aware that rapid innovation in the food processing industry can mean that even relatively new equipment might suffer functional obsolescence. In this case, however, the subject equipment had not been superseded by recent technological advances in spray drying so functional obsolescence was not a concern. And although food processing equipment can suffer from physical deterioration, very little was apparent here. Economic obsolescence is another consideration in valuing food processing equipment. I rely on market data – including interviews with experts – when determining the reduction in value, including a discount for ownership. In this case, a lesser percentage for economic obsolescence was applied to the general-purpose equipment than to the specialized equipment, including the dryer and pasteurizer.

Appraising food processing equipment

Credible valuation of food processing equipment depends on the appraiser’s understanding of the specialized machinery and equipment used in the industry. While a spray dry operation is clearly different from walnut processing, even food processing facilities that seem similar can be very different. An experienced appraiser will take the time to understand your operation, including equipment used in packaging, sanitizing, and safety, and will research the various components and specialty equipment in your facility, considering the operation as a whole, and will assess economic trends that may influence market values.

Valuations for an inheritance situation (IRS Estate and Gift Tax Return) will be different from appraisals for family law or a buy/sell situation. If you think you might need an appraisal of food processing equipment or would like a review of an appraisal you’ve received but aren’t sure about, give us a call at 530.795.5536. We’re here to help.

Jack Young, ASA—MTS/ARM, CPA

Equipment Appraisal & Appraisal Review

NorCal Valuation Inc.